JOBSITE SAFETY

General Safety Procedures

Safety must come first. As the solar industry has grown, unfortunately the number of injuries and fatalities has also grown. Every site is unique and requires a detailed analysis of the hazards and plans to mitigate any potential harm. General requirements of a safe work area include:

GENERAL SAFETY

-

The access and exit arrangements should be safe and clear of obstacles.

-

Communication arrangements should be safe and clear of obstacles.

-

Maintain a first aid kit to mitigate accidents involving personnel or any other person who may be in the vicinity.

-

Keep tools sharp and clean.

-

Don’t hold the switch button while carrying a plugged-in tool.

-

Consider what you wear – loose clothing and jewelry can get caught in moving parts.

-

Disconnect tools when not in use, before servicing and cleaning, and when changing accessories.

-

Keep away people who are not involved with the work.

-

Make use of an insulated tools kit.

-

Since the rooftop is located outdoors, adequate precaution should be taken to avoid sunburns, exhaustion, and de-hydration.

-

Use sunscreen, use a hat if necessary, wear light colored clothes and keep drinking a lot of water.

-

Always read the site safety notice and act accordingly.

SPECIFIC SAFETY

-

Grid connected PV systems are expected to have a lifetime of decades with maintenance/ modifications likely at some point over the period. It makes it essential for the PV system to be protected.

-

Switch enclosures must also be labeled with “Danger - contains live parts during daylight”.

-

Ensure that the solar isolation switch is off and the mains has been isolated. This may be located either on the main fuse board or near the inverter. The solar panels and the wiring to the inverter/fuse board will still remain live.

-

If the control equipment or cabling becomes complicated, or closer to the fire. Monitor fire spread, and contact branch operators.

-

As with any electricity generating equipment, do not approach or make contact with any parts that are not considered ‘dead & earthed’, and arrange for the attendance of the electricity authority for advice and guidance.

-

Before operating the Inverter, ensure that the power cable and wall outlet have been grounded properly.

-

Repairs or testing under power must only be performed by qualified technicians who are familiar with and qualified to work with the Inverter.

Importance of Personal Protective Equipment (PPE)

PPE is the last line of defense in protecting workers from hazards in the workplace. The

employer must try to eliminate workplace hazards or reduce them as much as possible, before

requiring workers to wear PPE, to protect them from a specific hazard

Major Safety Hazards

Types of Hazards

-

Physical Hazards

-

Electrical Hazards

-

Chemical Hazards

Physical Hazard - Personal Protection

Body Part

Head

Eye

Face

Hands and arms

Bodies

Feet

Protection Equipment

Safety helmet

Safety Glasses, Goggles

Face Shield

Gloves

Vests

Safety Shoes

NOTE:

If the right PPE is not worn properly or when needed is not available, or the PPE fails (for example, gloves leak), the hazard still exists; so the worker is not protected. PPE is not the most effective safety measure because it places only a barrier between the employee and the hazard. Workplace hazards that could cause injury include the following:

-

Intense heat

-

Impacts from tools, machinery and materials

-

Hazardous chemicals

-

Electric shock

-

Fire hazards

Safety helmet

Protection of the head is very important because injuries to the head are very serious. A hard hat is a type of helmet predominantly used in workplace environments such as industrial or construction sites to protect the head from injury due to falling objects, debris, rain, and electric shock.

Suspension bands inside the helmet divide the helmet’s weight and the force of any impact over the top of the head. It provides space of approximately 30 mm (1.2 inch) between the helmet’s shell and the wearer’s head, so that if an object strikes the shell, the impact is sensed less directly on the skull.

Types of Helmets

Class A Hard Hats

Protect you from falling objects

Protect you from electrical shocks up to 2,200 volts

Class B Hard Hats

Protect you from falling object

Protect you from electrical shocks up to 20,000 volts

Class C Hard Hats

Protect you from falling

Class D Bump Caps

Bump caps are designed to protect you from bumping your head on protruding objects. They are especially made from lightweight plastic

Safety Glasses

-

Safety glasses are forms of protective eye wear that usually enclose or protect the area surrounding the eye in order to prevent particulates, chemicals from striking the eyes. Goggles are frequently worn when using power tools such as drills or chainsaws to prevent flying particles from damaging the eyes.

-

Sunglasses or regular glasses are not appropriate safety glasses.

-

For employees who use spectacles they must use goggles that can fit comfortably over corrective eyeglasses without disturbing their alignment.

Hand Gloves

-

Tools and machines with a sharp edge can cut your hands. For electrical works, rubber insulating gloves are among the most important articles of personal protection. To be effective, electrical safety gloves must include high dielectric and physical strength, along with flexibility and durability.

-

Two kinds of gloves are commonly used: PVC Gloves and Cotton Gloves.

Safety belts/ Body harness

Safety belts or a harness provides the following support:

-

Personal protection against falling from high structures

-

Enables comfortable working position with protection against imbalance and slipping.

-

Climbing to a location that is inaccessible from inside the building/household using an anchorage and suspension line.

-

PVC coated jackets provide protection from extreme or harsh weather conditions, injury from sharp tools and chemicals or fluids that should not come in contact with the body.

Safety Shoes

-

Safety shoes protects you from electrical shocks & burns, extreme heat, extreme moisture (can lead to fungal infections) and slipping (oil, water, soaps, wax, and other chemicals can cause you to slip and fall.)

-

At work, heavy objects can fall on your feet. If you work around sharp objects, you can step on something sharp and injure your foot.

-

3-4 active modules produce a dangerous voltage for a person touching exposed wires. Therefore, safety precautions need to be employed.

-

If the inverter is disconnected from the modules or from the output AC side, high voltages remain may continue to exist.

Electrical Hazards

Risk to installers and maintenance personnel

-

Specific electrical hazards are related to maintenance activities on the electrical parts of the PV plant. Specifically, during array connection during installation and replacement of PV panels there are potential electrocution hazards.

-

The most common accidents are electrical shocks and burns, contraction of muscles and other severe injuries. These injuries can take place at anytime if proper safety measures are not followed. It is difficult to estimate the severity of electrical injury because if the human body is exposed to a voltage, it acts like a resistor and allows the current to pass.

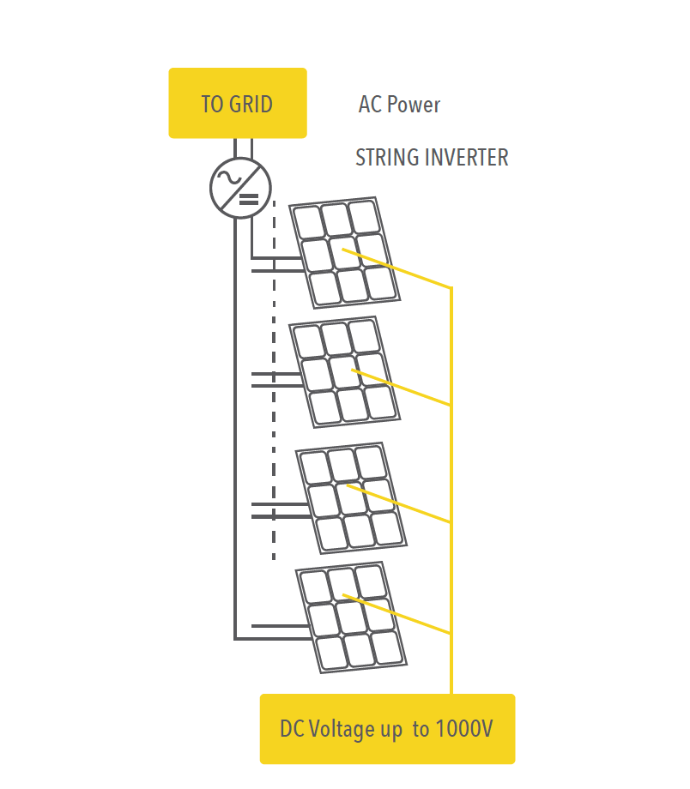

AC power turned ON

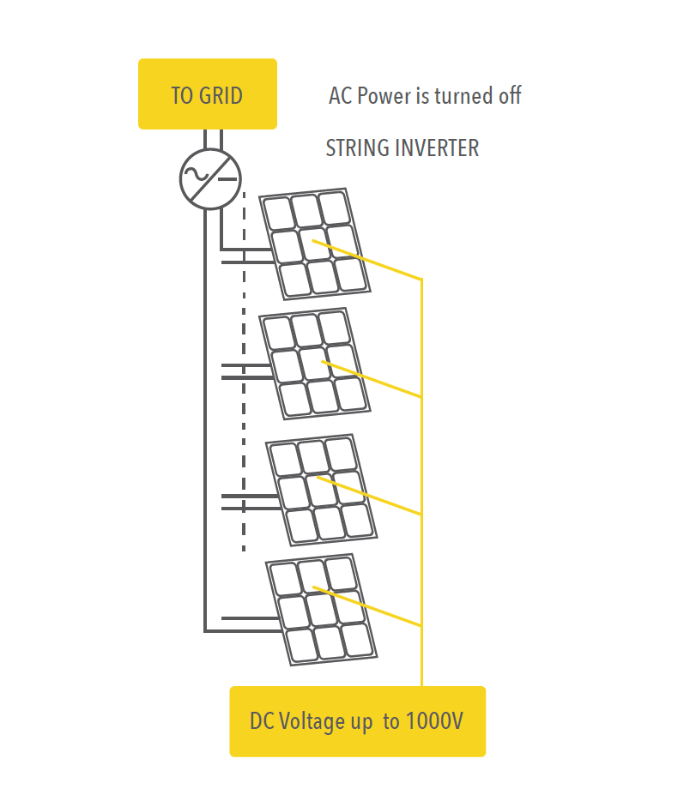

AC power turned ON AC power turned OFF

AC power turned OFFRisk to firefighters

-

False assumptions can lead to disasters. Firefighters commonly cut off electric grid supply to burning buildings as a precaution procedure before extinguishing the fire. They assume, that once the grid has been disconnected there is no risk of electrocution, allowing the spray of water.

-

Unfortunately, this assumption is not true in case of a RTPV system. PV systems are always energized when exposed to sunlight. Traditionally, rooftop PV systems operate at up to 1,000 V DC (modern systems can even go as high as 1,500 V). Opening disconnects interrupts current flow. Hazardous voltages remain even with disconnects open.

-

Always check the voltage between any conductor and any other wires, and to ground.

-

Always wear gloves and avoid touching conductive parts (e.g., battery terminals, metal and mounting frames) with bare hands.

-

Electric sparks and loose connection can lead to a fire. Take proper preventive measures:

-

Use insulated tools (e.g., spanners)

-

Ensure that the battery terminals are covered

-

Check contacts and voltage drop

-

Tighten up all screws

-

Check cable and terminal block periodically

-

The value of resistance varies with condition (Wet: 1,000 Ω - Dry: 100,000 Ω). Even a seemingly insignificant current (of order of mA) is also sufficient to cause damage. A list of DC and AC current (in mA) and their related electric shock hazards are given below:

|

Reaction after the Electric shock

|

DC Current

|

AC Current

|

| Perception: Tingle or warmth | 6 mA | 1 mA |

| Shock: Retain muscle control, response may result into injury and burns |

9 mA |

2 mA |

| Severe shock: Lose in muscle control, severe burns and asphyxia |

90 mA |

100 mA |

| Ventricular Fibrillation: may cause death |

500 mA |

100 mA |

| Heart Frozen: Temperature of human body rises, death occurs in minutes |

>1 A |

>1 A |

Chemical Hazards

Hydrogen is produced when a lead/acid battery is charged. Therefore, install battery in well-ventilated area and keep flames and equipment that create spark away from the battery. A multipurpose extinguisher is a good choice. Use of CO2 operated fire extinguisher should be avoided because they extinguish fire by removing oxygen. Fire Extinguishers category:

-

Class A: For fires involving conventional combustible materials such as paper and wood.

-

Class B: For fires involving flammable or combustible liquids or gases, greases and similar materials.

-

Class C: For fires involving energized electrical equipment.

-

Class K: For fires involving combustible metals

NOTE: For fire caused by electrical equipment use a powder and CO2 fire extinguisher

KEY POINTS TO REMEMBER

While most construction jobs are within easy access to medical care, some construction jobs are in more remote areas. The following items should be considered when you develop procedures for responding to emergencies. Someone who is not on the jobsite should know the following:

-

How many people are on the jobsite?

-

Are they expected to return at a specific time?

-

Do they have access to a phone service?

-

Do employees have the proper safety training they need for the work they are doing?

-

Are they carrying a first-aid kit?

-

Is there a nearby hospital or clinic?

-

Do employees have proper safety gear in good working condition (such as fall protection and other personal protective equipment)?

-

Is employee emergency-contact information such as phone number, person to contact, and any pertinent medical information latest and accessible?

-

What is their emergency plan?